Laser Engraving

Laser Engraving

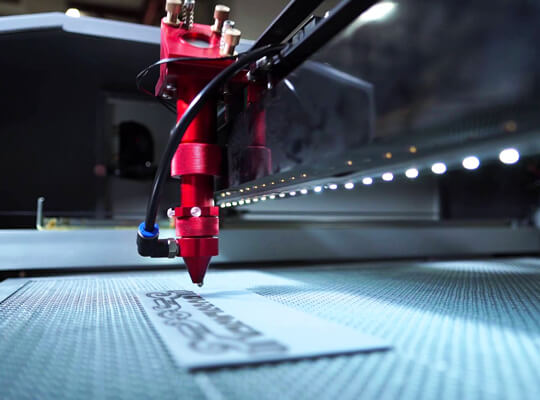

Laser engraving has been widely adopted in a lot of applications, and can be applied on materials such as wood, plastic, foam, metal, textile, glass and much more. Regarding foam industry, laser engrave cutting can be used not only for fabricating foam products, but for making foam injection mold tooling and heat embossing tools.

Before using larger engraving for foam products, CAD or similar drawing files of the custom fabricated foam product should be prepared ahead. With the laser beam from laser machinery, the foam surface will be engraved in wanted way. This process is automatic at high speed once the cutting program is set up.

Compared with general printing methods such as silk screen printing or heat transfer printing, laser engraved marks can be durable and consistent. Also laser cutting can be done without extra tooling cost. Laser engraving is a kind of precise cutting with constant quality, and it requires low order quantity.

Main Advantages:

- Deliver high precision and consistent custom engraving marks.

- Able to work with no need of production mold and high tooling cost.

- Versatile to apply on a wide range of foam materials.

Related Foam Material:

- EVA Foam

- Polyethylene Foam

- Polyurethane Foam

- Vinyl Nitrile Foam

- Silicone Foam

Applications:

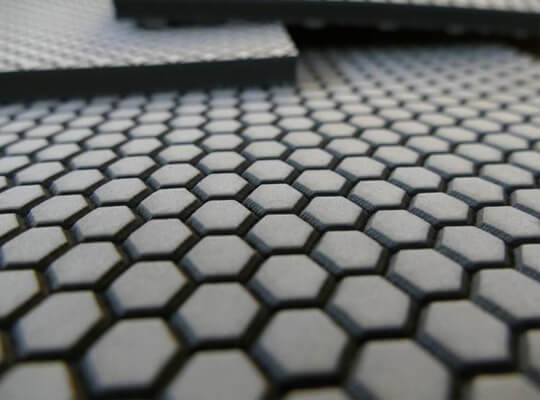

- Foam Sheets

- Foam Mats

- Foam Grips

- Foam Composites

- Custom Foam Products