Foam Printing

Foam Printing

Foam printing technique can help customer to brand foam products in wanted way. With color printing, foam products can be quite attractive and different from other competitor’s product. Just with a simple Logo colorfully shown on a foam product, it can totally make a difference. Typically we utilize two kinds of printing methods for our foam products: hear transfer printing and silk screen printing.

Heat Transfer Printing

Regarding heat transfer printing, it is mostly used for clothing industry which can used to print vivid and colorful image onto clothing. For foam products, we use two kinds of heat transfer printing methods, rotary heat transfer printing and flat press heat transfer print. The first one is used for printing color foam mats or foam pads in large quantity volume. The flat press heat transfer is used for applying custom logo onto foam products. A custom print mold is needed to be made for utilizing both methods. The heat transfer printing actually work under heating and print design is attached on a layer of plastic film.

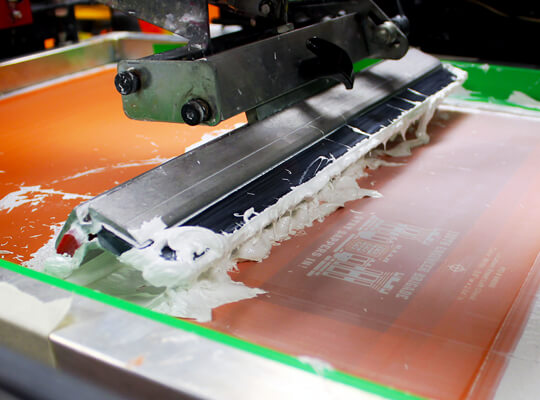

Silk Screen Printing

Silk screen printing is a low cost printing methods for foam products. It is widely used for logo printing on foam products such as EVA foam yoga block and printed yoga mat. In order to use silk screen printing, a custom made print plate is needed. The plate mold can be made based on electronic artwork design. Silk screen printing is suitable for print simple and easy design, not suitable for complicated and too colorful images. They are low cost printing methods used a lot for logo printing.

Main Advantages:

- Multiple ways to make custom color printing based on customer needs.

- Make foam products vivid and eye-catching

- Versatile to work with a broad range of foam materials

Related Foam Material:

- EVA Foam

- Polyethylene Foam

- PVC Nitrile Foam

Applications:

- Foam Mats

- Foam Pads

- Foam Packaging

- Foam Composites

- Private Label Foam Products