Foam Lamination

Foam Lamination

Foam Lamination is mostly a must process for making foam composites, which can make two kinds of material combined together and works as one part. It is quite useful process that can bond foam no only with foam, but also combine with other material including adhesive, fabric, film, foil or other materials. It is an essential way to make foam composite and complicated foam products.The typical two lamination methods are PSA lamination and flame lamination (heat lamination).

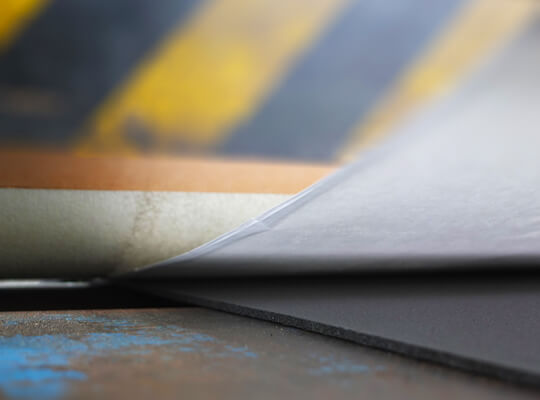

PSA lamination

PSA stands for pressure sensitive adhesive. PSA lamination is a process that can make foam sheet or roll with adhesive back. PSA lamination is performed by adhesive laminator. It is usually used for foam rolls. After one roll of foam goes through adhesive laminator, it can be applied with a layer of adhesive back on one side along with the release liner. PSA lamination is a must process to make adhesive foam tapes.

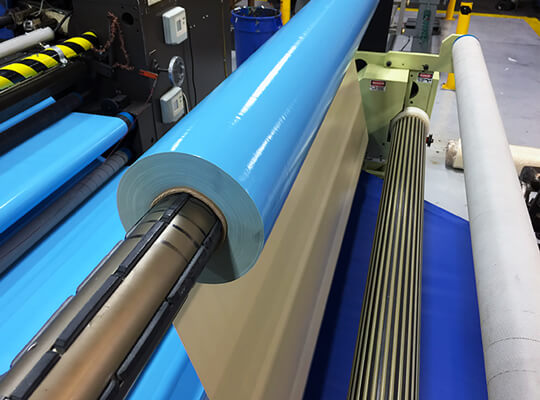

Flame lamination / Heat lamination/ Thermal Lamination

Flame Lamination also called heat lamination and thermal lamination. Flame laminator can create a high temperature that foam sheet can get melted on surface. When two pieces of foam sheets go through heat lamination machine at the same time, they can be bond together firmly with hot melted surface. Flame lamination can be used for both foam sheets and foam rolls, and it works with a lot of foam materials including EVA foam, PE foam, PU foam, PVC/ Nitrile Foam etc..

Main Advantages:

- A sophisticated way to bond foam with foam or other materials together.

- High efficient to make foam sheet or roll with PSA adhesive back

- A vital foam fabrication process for making foam composites

Related Foam Material:

- EVA Foam

- Polyethylene Foam

- Polyurethane Foam

- Vinyl Nitrile Foam

- Foam Rubbers – Neoprene foam, EPDM foam and SBR foam

Applications:

- Foam Sheets

- Foam Rolls

- Foam Packaging

- Foam Tapes

- Foam Composites

- Custom Foam Products