Foam Grinding

Foam Grinding

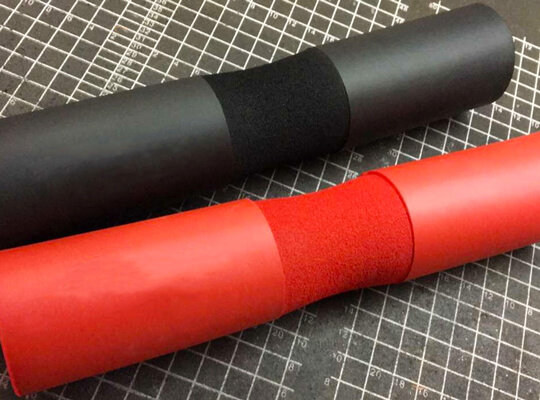

Some foam comes naturally with thick outer skin, when you want to find a way to remove it, foam grinding can be a good choice. They are frequently used for polish foam surface and grind out wanted foam shapes by abrasion method.

Foam grinding process is mainly used to make custom foam hand grip and foam tubes with a polished surface. In order to make custom grinding foam products, a custom grinding wheel mold is needed for facilitate the process. The grinding wheel is made of plenty of abrasive particles based on the size of foam tubes, and it can be large or small. While rolling on a rotary mandrel, the tiny abrasive particles on grinding wheel work greatly to polish foam tubes or pipes into wanted shapes.

Foam grinding technique can apply for both overall surface polishing and partial surface polishing. It works with a lot of closed cell foam materials including PVC Nitrile foam, silicone foam and EVA foam. They are frequently used for making foam tubes and hand grips in various shapes and sizes.

Main Advantages:

- High efficient way to remove and polish foam surface skin

- Essential way to make custom foam grips and tubes

- Versatile to work with a wide range of closed cell foam materials

Related Foam Material:

- EVA Foam

- Vinyl Nitrile Foam

- Silicone Foam

Applications:

- Foam Grips

- Foam Tubes/ Pipes

- Custom Foam Products